KC LNG Tech 주메뉴

전체메뉴

KC CCS

KC CCS

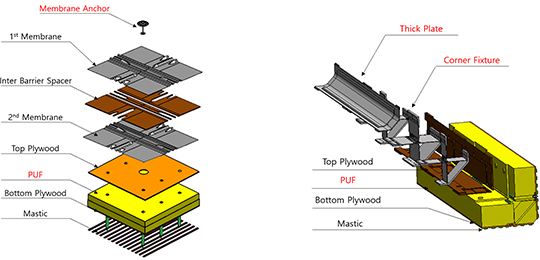

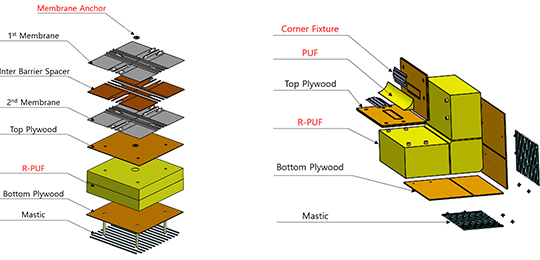

KC-1 layer structure

KC-1 layer structure

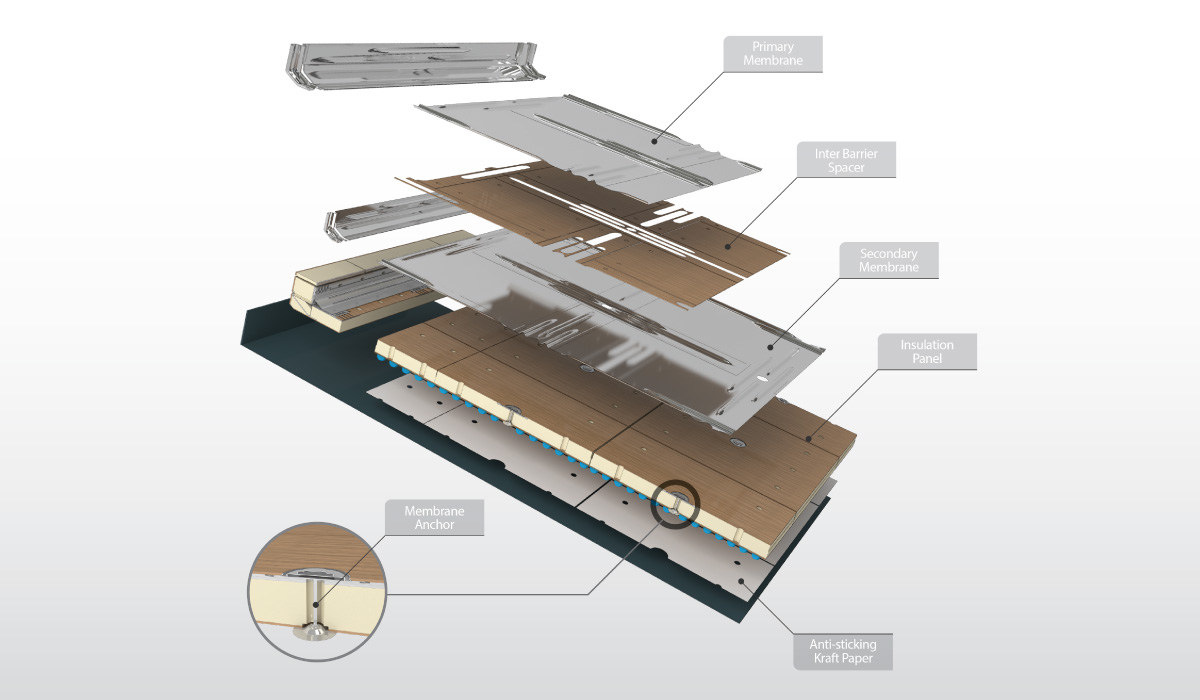

Consisting of 1st and 2nd membrane made of SUS 304L with non-continuous corrugation

Used to fix parts of membrane to the insulation panels

A bonded sandwich structure with an only one layer including back plywood, polyurethane foam and top plywood

Maintaining regular distance between primary and secondary membrane , which doesn’t have an influence on secondary membrane in case of the damage on primary membrane

Consisting of wing plate and base plate to make corner panel fixed to hull

Fixed to corner fixture and functioning as a structure

| KC-1 | KC-2 | |

|---|---|---|

| Primary Barrier | Stainless 1.5mm (non-continuous corrugation) |

Stainless 1.2mm (non-continuous corrugation) |

| Secondary Barrier | Stainless 1.5mm (non-continuous corrugation) |

Stainless 1.2mm (non-continuous corrugation) |

| Insulation Panel | PUF | R-PUF |

| 174K LNGC BOR (Thickness) | 0.12 %/day (256.5mm) | 0.07 %/day (450mm) |